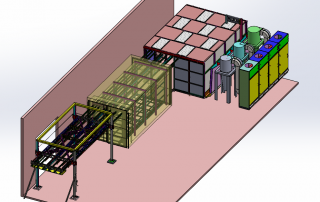

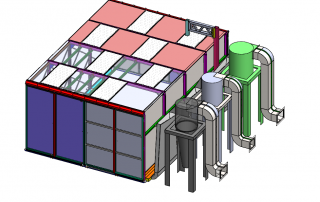

Aim : To Design and Build Powder Spray Booth with Recyclable Filtration System and Automated Overhead Tracks

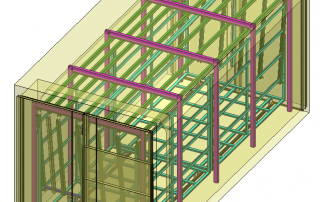

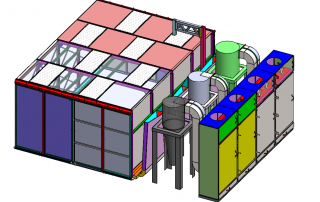

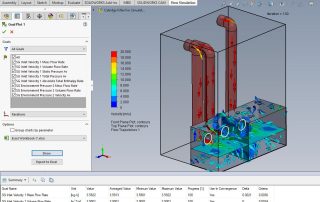

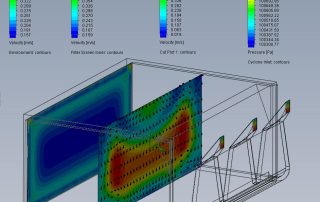

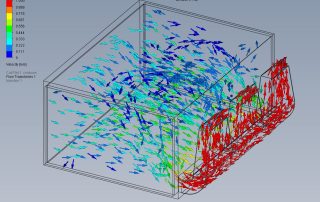

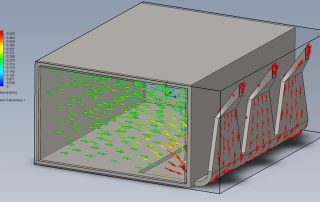

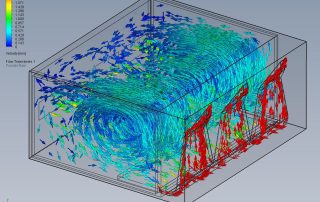

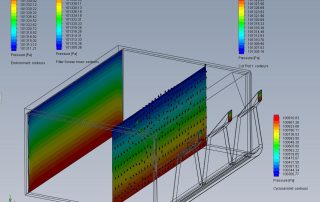

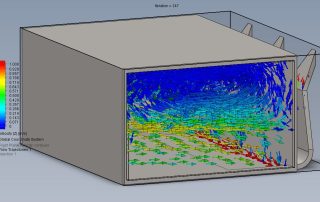

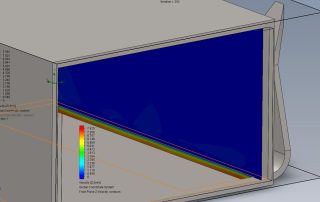

a) Negative Pressure Spray Booth

- booth size (1.5mm) mild steel plates with reinforcing steel ribs

- dismantlable design

- ceiling and side wall, LED lighting 100W x 12 pieces

- integration of existing 3x cyclones (mountings, duct works, electrical, etc)

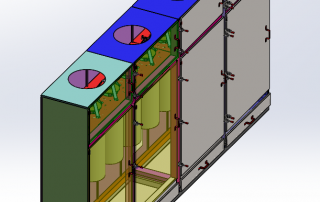

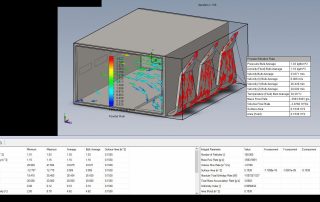

b) Filter Module

- self cleaning drum filters 6 pieces Ø325×660 Japan PTFE coated polyester (washable)

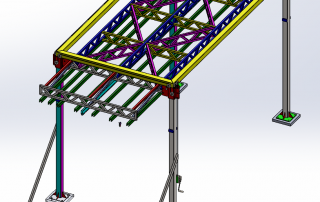

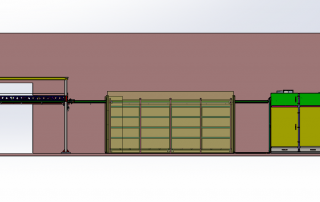

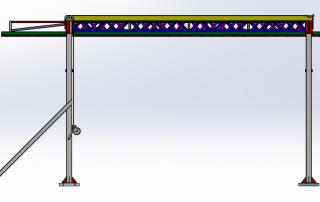

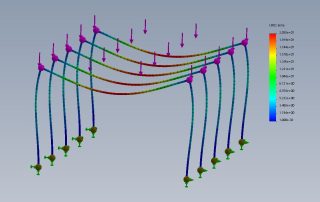

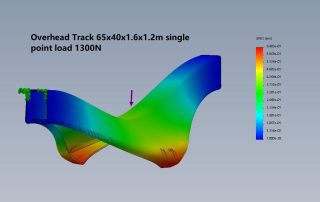

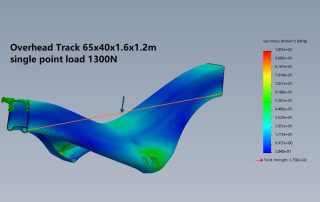

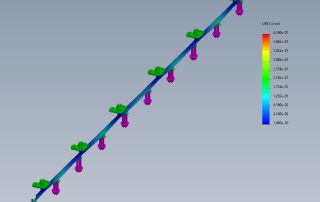

c) Overhead System

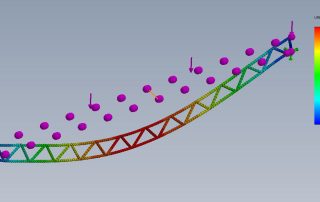

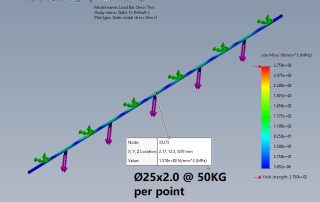

- 6 pieces 20m Upper Steel Track

- Ø50 upper track rollers 72 pieces

- laterally movable upper tracks in spray booth section with alignment system

- motor drive, sheave & cable system for parts in and out

- exit overhead upper tracks hand crank pulley lifter system (for forklift clearance)

- operator control panel

d) Floor Tracks and Low Skid Trolley

- 2 pieces 20m angle bar floor tracks for trolley

- low skid steel trolley with grooved wheels

e) Oven Repair & Modifications

- 4 pieces 2 mm thickness door replacement with new locks, gasket and insulation

- ceiling modifications for mounting of upper tracks

GALLERY

3D Modelling

Real Life Model

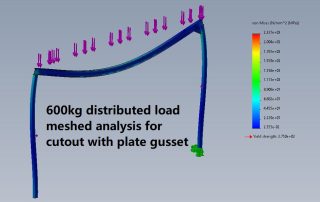

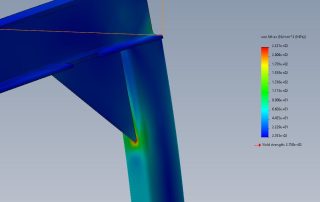

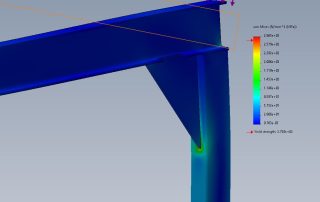

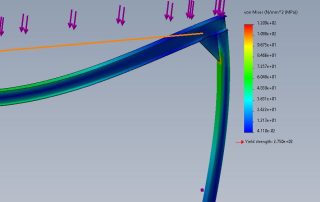

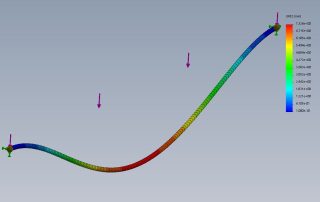

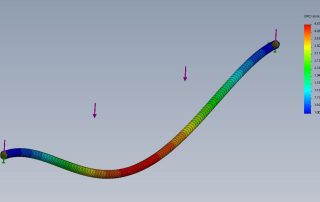

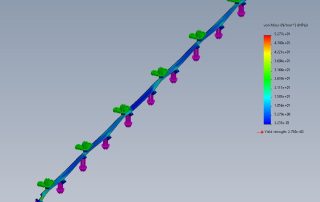

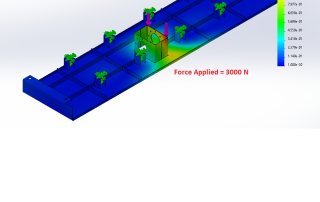

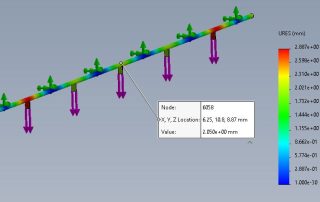

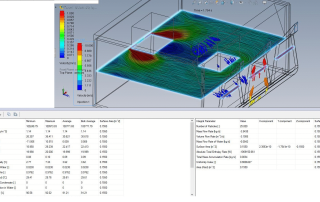

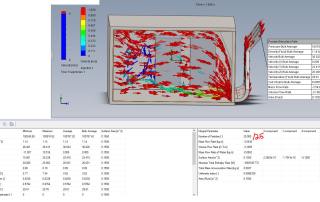

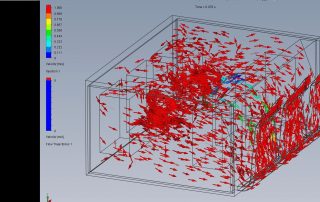

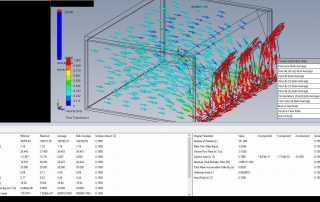

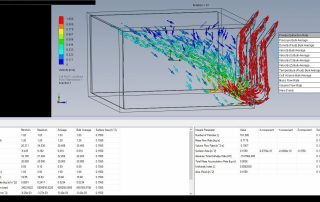

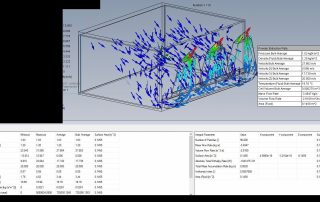

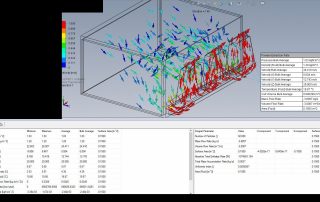

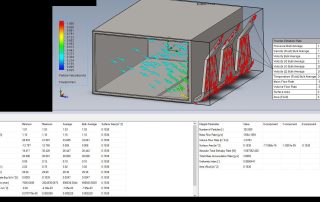

Finite Element Analysis (FEA) [Structure Strength Study]