The evolution of technology has opened different gates for people to invent advanced products that can help on a day-to-day basis, including of course are the computers and laptops we use every day. Now, computers are changing too.

Lots of technological innovations are popping up especially in industrial automation and control systems. If you are new to PLC programming, you’ll probably ask a lot of questions regarding PLCs and its function. Programmable Logic Controllers or PLCs, are one of the most important parts of control systems.

It is invented by Richard “Dick” Morley, known as the Father of the PLC. He worked on radar, bombs, and other electronics for Lab for Electronics. His curiosity to find a better way to control machines helped a lot in making processes easier for people and companies.

What does PLC do and where can you apply it?

PLCs are typically used to take control of a machine or a manufacturing process. Like modern computers, PLCs have a CPU that can do two distinct programs: the operating system and the user program.

The operating system performs the user program, handles hot and warm restart, manages the memory storage, updates the process image tables, and detects and calls interruptions. This program does the functions that are not related to a control task.

On the other hand, the user program initiates all the conditions in order to begin a specific task. It performs interrupts and is assigned to handle errors and evaluate binary input signals. This is a program utilized to work on automated tasks provided there is a user to create it.

How and why did PLC replace the traditional relay controls?

An old relay control board

The replacement of traditional relay controls is done by the demand of the market. People do plenty of control upgrades. The old mechanical days are long gone and customers are demanding to substitute them all by PLCs. Traditional relay controls and PLCs have their own strengths and weaknesses depending on the levels of functions. Some prefer the use of mechanical relays but most industrial digital computers now have PLCs.

What are the common brands of PLC?

The common brands of PLC you will see in the market today include Omron PLC, Mitsubishi PLC, and Siemens PLC. These three have a large product base, different hardware that varies per situation, and thousands of programmers available. Stick to these brands if you are searching for PLCs with great distributorship and extensive distribution.

Why should you use PLC programming?

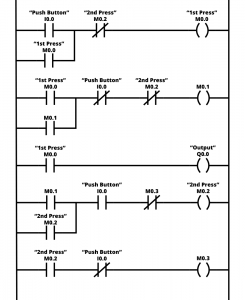

If you are not familiar with it yet, PLC programming is designing and implementing control applications based on the demand of the clients. This uses a PLC program that lists down instructions that serve as the logic. These instructions, or programming language, is called the ladder diagram.

Ladder diagram example

PLCs have a lot of benefits including its speed, flexibility, reliability, and low power consumption. People in the industry use PLC programming simply because it helps them control and monitor the production processes. Without this, there won’t be an easy operator interface and good documentation facilities for businesses.

Do you have a need to upgrade your old machinery with PLC automation? The experts at AMC Dynamics can you give you a free quote.

![Dummies Guide to Industrial Revolution 4.0 [Updated 2020]](https://amcdynamics.com/wp-content/uploads/2017/10/industrial-revolution-500x383.jpg)