PRECISION ENGINEERING

As specialists in Precision Engineering, we are able to use our extensive engineering experience & machine tools to provide a solution to any engineering requirement on any project size.

MACHINING

In the area of machining, we are specialized in high complex, high precision manufacturing of critical components with a huge variety and a high grade of automation. We are a leading player in the machining of high mix, low volume and high complexity components. We can work with a wide range of materials, from aluminum and titanium to stainless steel and beyond and can combine functionalities into the smallest number of building blocks. Our product range varies from small ultra-precision parts to large structural components.

DESIGN & PROTOTYPING

Combining our internal capabilities for quick turn parts and an established network of partners, we offer the widest range of prototype options to our customers. Our advanced 3D prototyping technologies yield models that closely emulate the look, feel and functionality of production components. Part accuracy is directly controlled by computer-aided solid models (CAD) and manufacturing (CAM) software. AMC Dynamics offers a wide range of file conversions, from IGES, STEP, STL, Parasolid, Solidworks, and Pro-E.

Our capabilities in Prototyping include:

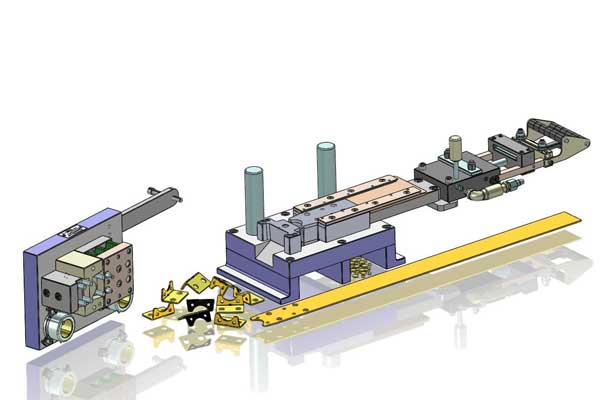

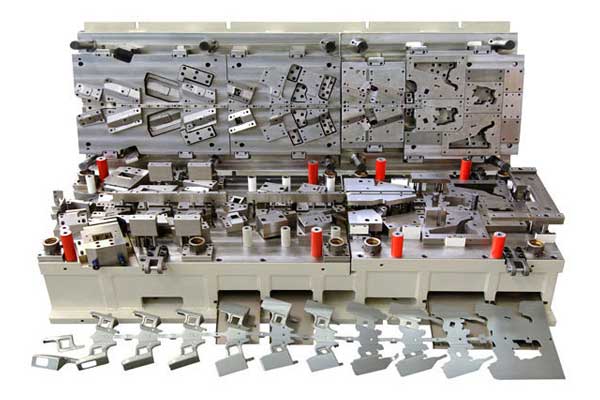

TOOLS & DIES MAKING CAPABILITIES

AMC Dynamics is an organization originating from the die making profession. Our specialization is the construction of high tech tooling for highly technical products such as: aircraft stamped parts, medical stamped components, firearms components, automotive stamped parts etc.